Maximising the Performance of PCD Router Tooling in Woodworking

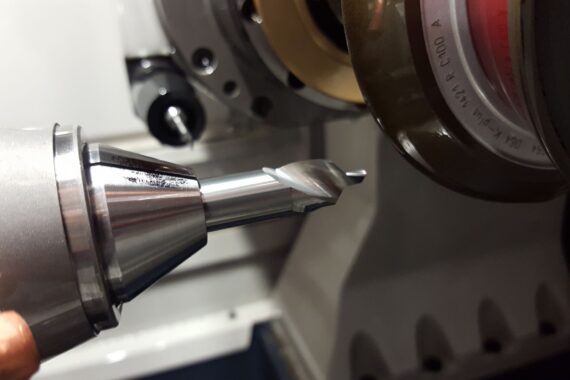

At the forefront of CNC cutting tools manufacturing, we take pride in providing our clients with exceptional cutting tools that immensely benefit their woodworking workshop’s precision, efficiency, and productivity. One such cutting tool that has revolutionised the woodworking sector is the PCD (polycrystalline diamond) Compression router cutter. These cutters are revered for their unparalleled performance…