TAPSP 8-36UNF R50UNI HARDLUBE

Price range: £25.29 through £85.81

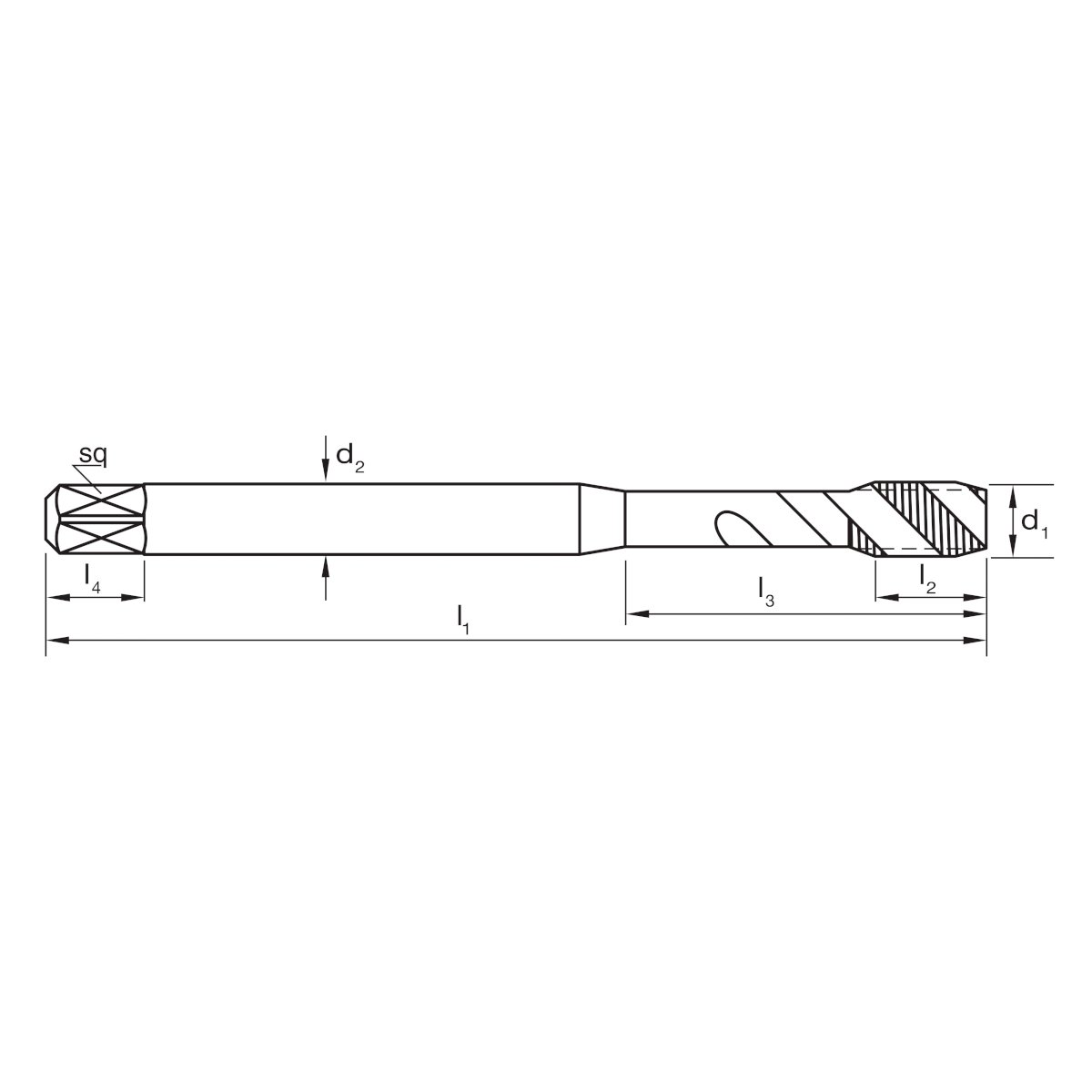

| pitem | d1 | tpi | limit | lengthl1mm | diameterd2mm | sq | lengthl4mm | z | RRP (inc GST) |

Image | Info |

|---|---|---|---|---|---|---|---|---|---|---|---|

| T6920284 | #4 | 48 | 2BX | 56 | 3.5 | 2.7 | 6 | 3 | £29 |

|

|

| T6920351 | #6 | 40 | 2BX | 56 | 4 | 3 | 6 | 3 | £25 |

|

|

| T6920417 | #8 | 36 | 2BX | 63 | 4.5 | 3.4 | 6 | 3 | £25 |

|

|

| T6920483 | #10 | 32 | 2BX | 70 | 6 | 4.9 | 8 | 3 | £27 |

|

|

| T6920635 | 1/4 | 28 | 2BX | 80 | 7 | 5.5 | 8 | 3 | £39 |

|

|

| T6920794 | 5/16 | 24 | 2BX | 90 | 6 | 4.9 | 8 | 3 | £44 |

|

|

| T6920953 | 3/8 | 24 | 2BX | 90 | 7 | 5.5 | 8 | 3 | £47 |

|

|

| T6921270 | 1/2 | 20 | 2BX | 100 | 9 | 7 | 10 | 4 | £60 |

|

|

| T6921588 | 5/8 | 18 | 2BX | 100 | 12 | 9 | 12 | 4 | £86 |

|

| ISO | VDI | Description | Condition | Hardness | Strength | Optimal |

|---|---|---|---|---|---|---|

| P | 1 | Steel - Non-alloy, cast & free cutting (~ 0.15 %C) | Annealed | 125 | 440 | |

| P | 2 | Steel - Non-alloy, cast & free cutting (~ 0.45 %C) | Annealed | 190 | 640 | |

| P | 3 | Steel - Non-alloy, cast & free cutting (~ 0.45 %C) | Quenched & Tempered | 250 | 840 | |

| P | 4 | Steel - Non-alloy, cast & free cutting (~ 0.75 %C) | Annealed | 270 | 910 | |

| P | 6 | Steel - Low alloy & cast < 5% of alloying elements | Annealed | 180 | 610 | |

| P | 7 | Steel - Low alloy & cast < 5% of alloying elements | Quenched & Tempered | 275 | 930 | |

| P | 10 | Steel - High alloy, cast & tool | Annealed | 200 | 680 | |

| P | 12 | Steel - Corrosion resistant & cast - Ferritic / Martensitic | Annealed | 200 | 680 | |

| P | 13 | Steel - Corrosion resistant & cast - Martensitic | Quenched & Tempered | 240 | 810 | |

| M | 14.1 | Stainless Steel - Austenitic | Age Hardened | 180 | 610 | |

| M | 14.2 | Stainless Steel - Duplex | 250 | 840 | ||

| K | 15 | Cast Iron, Grey (GG) - Ferritic / Pearlitic | 180 | 610 | ||

| K | 16 | Cast Iron, Grey (GG) - Pearlitic | 260 | 880 | ||

| K | 17 | Cast Iron, Nodular (GGG) - Ferritic | 160 | 570 | ||

| K | 18 | Cast Iron, Nodular (GGG) - Pearlitic | 250 | 840 | ||

| K | 19 | Cast Iron, Malleable - Ferritic | 130 | 460 | ||

| K | 20 | Cast Iron, Malleable - Pearlitic | 230 | 780 | ||

| N | 21 | Aluminum & Magnesium, wrought alloy - Non Heat Treatable | 60 | 210 | ||

| N | 22 | Aluminum & Magnesium, wrought alloy - Heat Treatable | Age Hardened | 100 | 360 | |

| N | 23 | Aluminum & Magnesium, cast alloy ?12% Si - Non Heat Treatable | 75 | 270 | ||

| N | 24 | Aluminum & Magnesium, cast alloy ?12% Si - Heat Treatable | Age Hardened | 90 | 320 | |

| N | 25 | Aluminum & Magnesium, cast alloy >12% Si - Non Heat Treatable | 130 | 460 | ||

| N | 26 | Copper & Copper alloys (Brass/Bronze) - Free cutting, Pb > 1% | 110 | 390 | ||

| N | 27 | Copper & Copper alloys (Brass/Bronze) - Brass (CuZn, CuSnZn) | 90 | 320 |