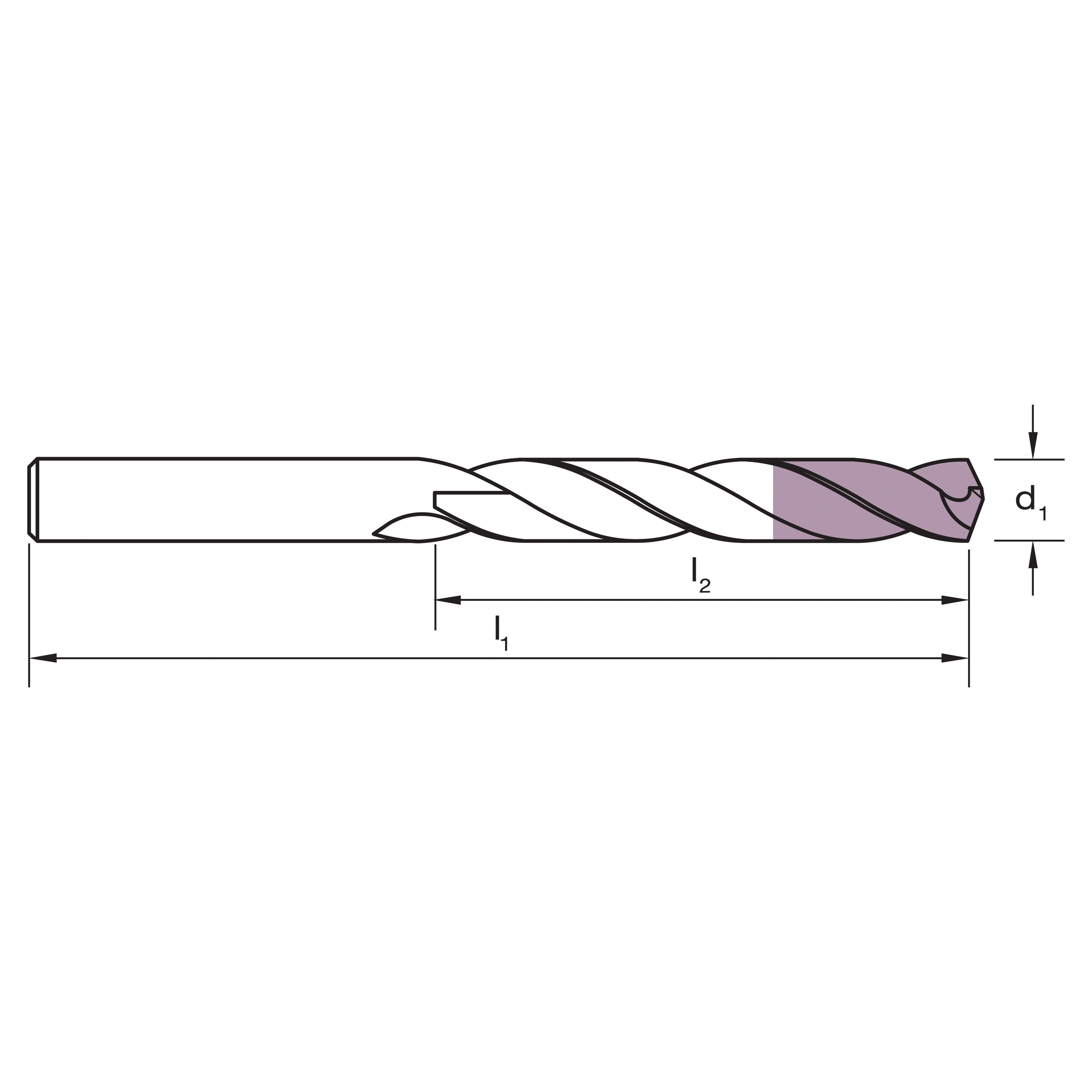

Jobber Drill Set D179, 29 Pce, Viper Plus, HSS, TiALN, DIN338

£78.66 – £195.90

Jobber Drill Set D179, 29 Pce, Viper Plus, HSS, TiALN, DIN338

£78.66 – £195.90

Jobber Drill Set D179, 29 Pce, Viper Plus, HSS, TiALN, DIN338

| pitem | description | pieces | range | case | RRP (inc GST) |

Image | Info |

|---|---|---|---|---|---|---|---|

| D179S3 | S3 | 29 | 1/16 - 1/2 x 64ths | ABS | £196 |

|

|

| D179SM2 | SM2 | 19 | 1.0 – 10.0mm x 0.5mm rises | ABS | £79 |

|

|

| D179SM3 | SM3 | 25 | 1.0 – 13.0mm x 0.5mm rises | ABS | £172 |

|

| ISO | VDI | Description | Condition | Hardness | Strength | Optimal |

|---|