Carbide Endmill, E464 R40/42 Ti, DIN6527L- Harmony

Price range: £31.14 through £230.49

Carbide Endmill, E464 R40/42 Ti, DIN6527L- Harmony

Price range: £31.14 through £230.49

Carbide Endmill, E464 R40/42 Ti, DIN6527L- Harmony

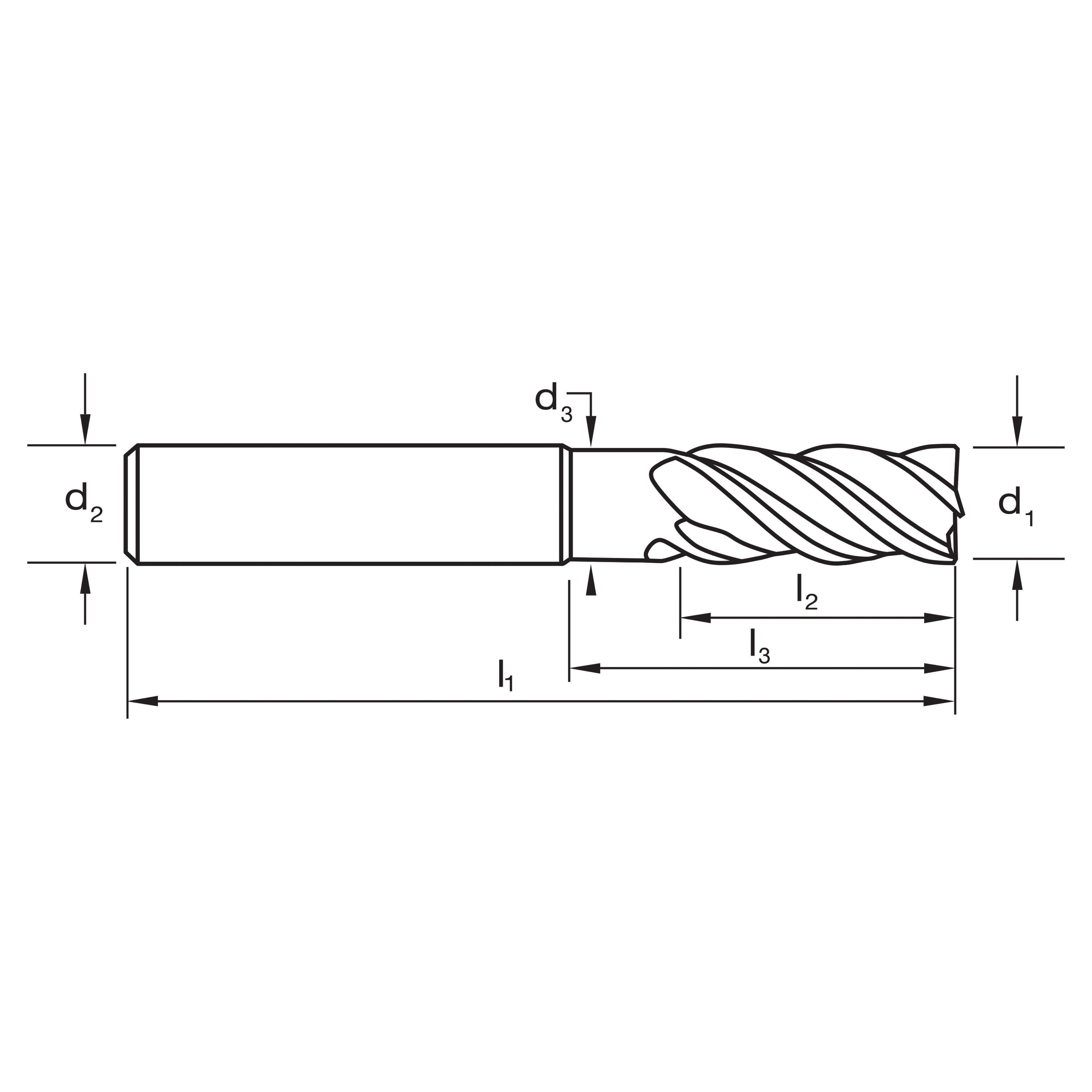

| pitem | diameterd1mm | diameterd1inch | lengthl1mm | lengthl2mm | lengthl3mm | diameterd2mm | RRP (inc GST) |

Image | Info |

|---|---|---|---|---|---|---|---|---|---|

| E4640600 | 6.00 | NA | 57 | 13 | 21 | 6 | £31 |

|

|

| E4640800 | 8.00 | NA | 63 | 19 | 27 | 8 | £43 |

|

|

| E4641000 | 10.00 | NA | 72 | 22 | 32 | 10 | £63 |

|

|

| E4641200 | 12.00 | NA | 83 | 26 | 38 | 12 | £97 |

|

|

| E4641600 | 16.00 | NA | 92 | 32 | 44 | 16 | £157 |

|

|

| E4642000 | 20.00 | NA | 104 | 38 | 54 | 20 | £230 |

|

| ISO | VDI | Description | Condition | Hardness | Strength | Optimal |

|---|---|---|---|---|---|---|

| S | 37.1 | Titanium & Titanium alloys - Alpha alloys | 860 | |||

| S | 37.2 | Titanium & Titanium alloys - Alpha / Beta alloys | Annealed | 960 | ||

| S | 37.3 | Titanium & Titanium alloys - Alpha / Beta alloys | Age Hardened | 1170 | ||

| S | 37.4 | Titanium & Titanium alloys - Beta alloys | Annealed | 830 | ||

| S | 37.5 | Titanium & Titanium alloys - Beta alloys | Age Hardened | 1400 |