DIN TAP T297 Straight Flute, Metric, VH, M, TiCN

£140.67 – £449.12

DIN TAP T297 Straight Flute, Metric, VH, M, TiCN

£140.67 – £449.12

DIN TAP T297 Straight Flute, Metric, VH, M, TiCN

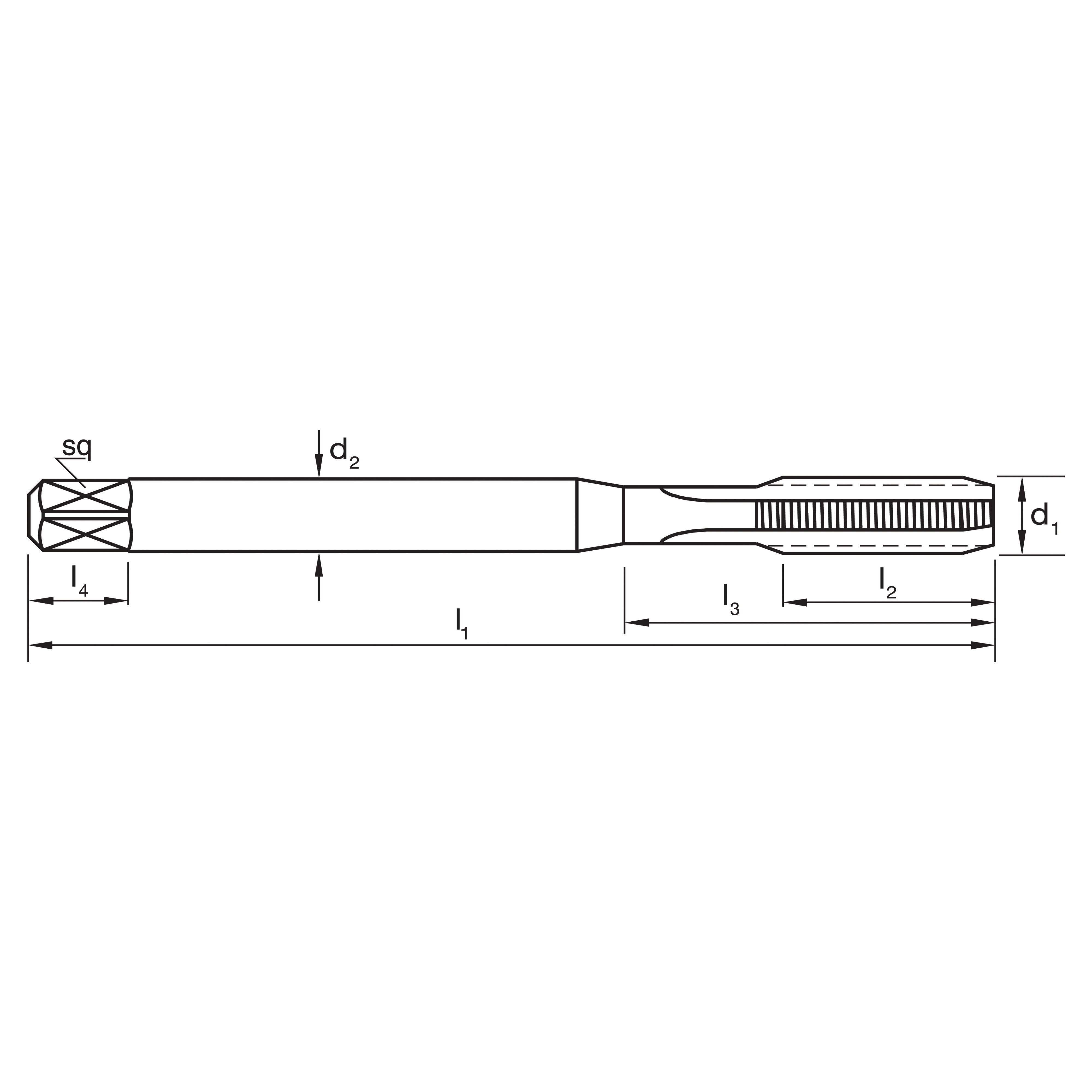

| pitem | d1 | limit | lengthl1mm | lengthl2mm | diameterd2mm | sq | lengthl4mm | z | Pitch | RRP (inc GST) |

Image | Info |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T2970300 | M3 | 6HX | 56 | 11 | 3.5 | 2.7 | 6 | 4 | 0.50 | £141 |

|

|

| T2970400 | M4 | 6HX | 63 | 13 | 4.5 | 3.4 | 6 | 4 | 0.70 | £144 |

|

|

| T2970500 | M5 | 6HX | 70 | 16 | 6 | 4.9 | 8 | 4 | 0.80 | £152 |

|

|

| T2970600 | M6 | 6HX | 80 | 19 | 6 | 4.9 | 8 | 5 | 1.00 | £181 |

|

|

| T2970800 | M8 | 6HX | 90 | 22 | 8 | 6.2 | 9 | 5 | 1.25 | £235 |

|

|

| T2971000 | M10 | 6HX | 100 | 24 | 10 | 8 | 11 | 5 | 1.50 | £254 |

|

|

| T2971200 | M12 | 6HX | 110 | 28 | 9 | 7 | 10 | 5 | 1.75 | £297 |

|

|

| T2971600 | M16 | 6HX | 110 | 32 | 12 | 9 | 12 | 6 | 2.00 | £362 |

|

|

| T2972000 | M20 | 6HX | 140 | 34 | 16 | 12 | 15 | 6 | 2.50 | £449 |

|

| ISO | VDI | Description | Condition | Hardness | Strength | Optimal |

|---|---|---|---|---|---|---|

| P | 9 | Steel - Low alloy & cast < 5% of alloying elements | Quenched & Tempered | 350 | 1180 | |

| P | 11 | Steel - High alloy, cast & tool | Hardened & Tempered | 325 | 1100 | |

| P | 13 | Steel - Corrosion resistant & cast - Martensitic | Quenched & Tempered | 240 | 810 | |

| N | 27 | Copper & Copper alloys (Brass/Bronze) - Brass (CuZn, CuSnZn) | 90 | 320 | ||

| H | 38.1 | Hardened steel | Hardened & Tempered | 45 | ||

| H | 38.2 | Hardened steel | Hardened & Tempered | 55 | ||

| H | 39.1 | Hardened steel | Hardened & Tempered | 58 | ||

| H | 39.2 | Hardened steel | Hardened & Tempered | 62 | ||

| H | 40 | Cast Iron - Chilled | Cast | 400 | 1350 | |

| H | 41 | Cast Iron | Hardened & Tempered | 55 |