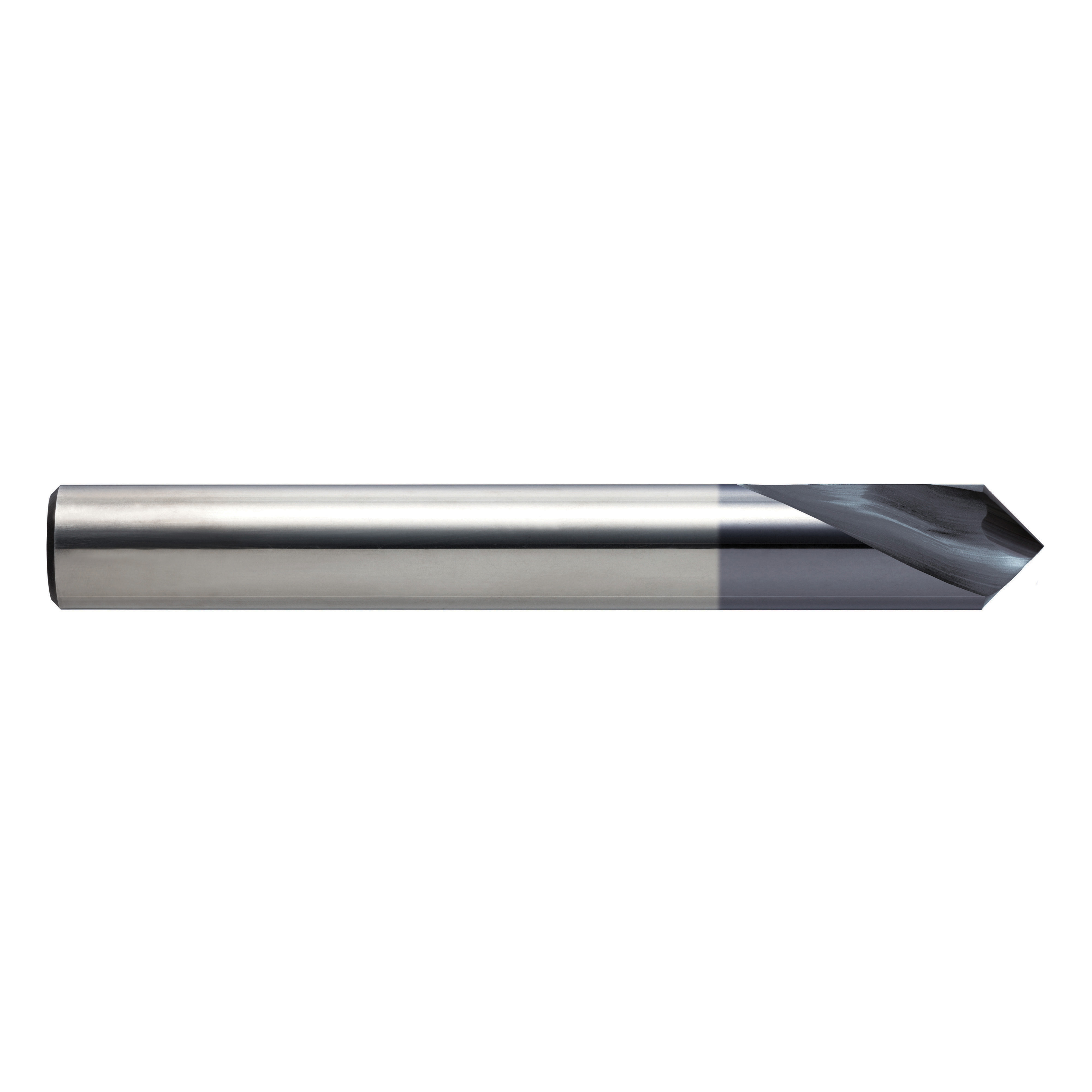

Carbide Spot Drill D364 90°

£23.15 – £204.28

Carbide Spot Drill D364 90°

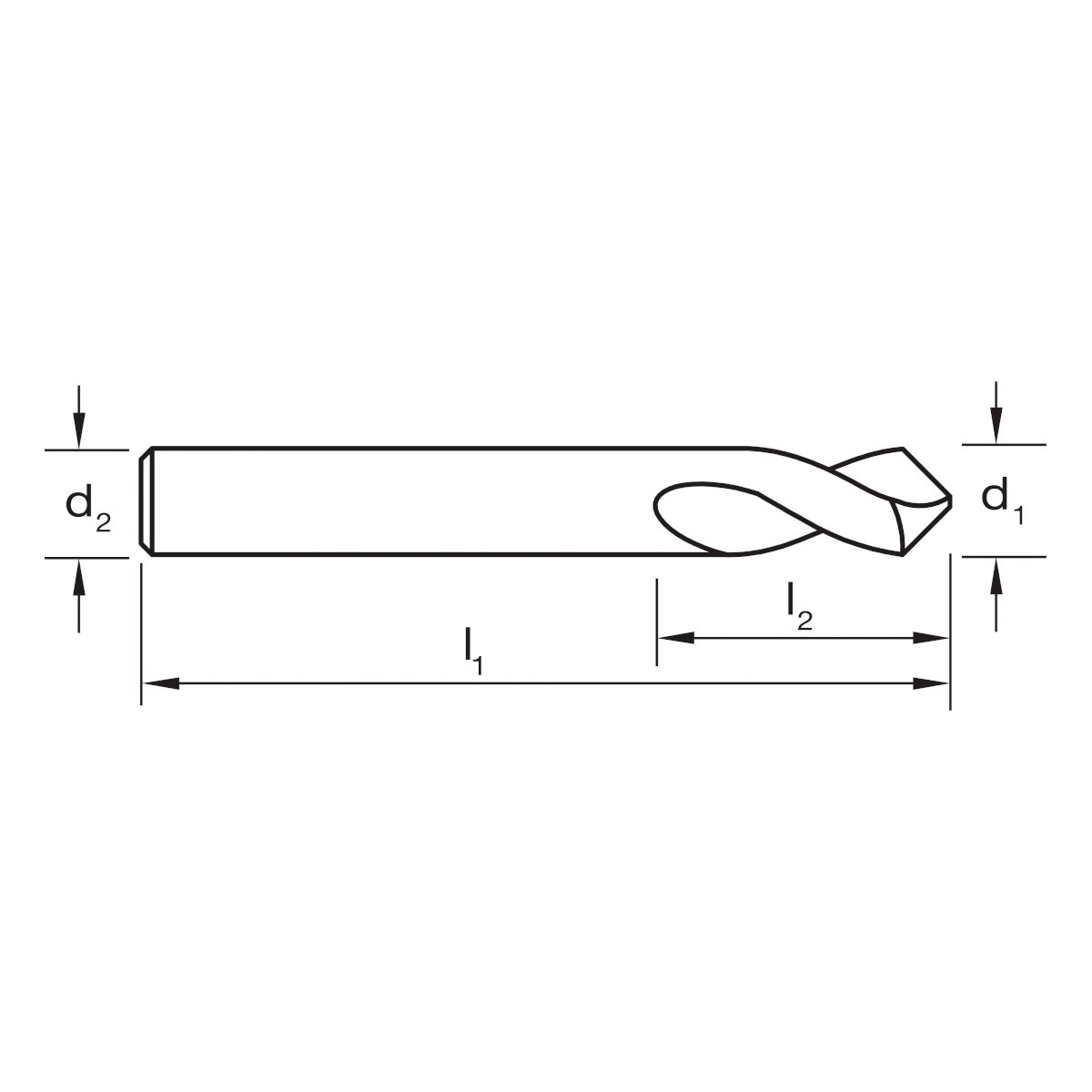

| pitem | diameterd1mm | lengthl1mm | lengthl2mm | diameterd2mm | RRP (inc GST) |

Image | Info |

|---|---|---|---|---|---|---|---|

| D3640300 | 3.00 | 46 | 9 | 3 | £23 |

|

|

| D3640400 | 4.00 | 55 | 12 | 4 | £30 |

|

|

| D3640500 | 5.00 | 62 | 15 | 5 | £31 |

|

|

| D3640600 | 6.00 | 66 | 18 | 6 | £31 |

|

|

| D3640800 | 8.00 | 79 | 23 | 8 | £40 |

|

|

| D3641000 | 10.00 | 89 | 24 | 10 | £52 |

|

|

| D3641200 | 12.00 | 102 | 24 | 12 | £67 |

|

|

| D3641600 | 16.00 | 115 | 26 | 16 | £116 |

|

|

| D3642000 | 20.00 | 131 | 35 | 20 | £204 |

|

| ISO | VDI | Description | Condition | Hardness | Strength | Optimal |

|---|