What Makes Slot Drills Perfect for Precise Cuts

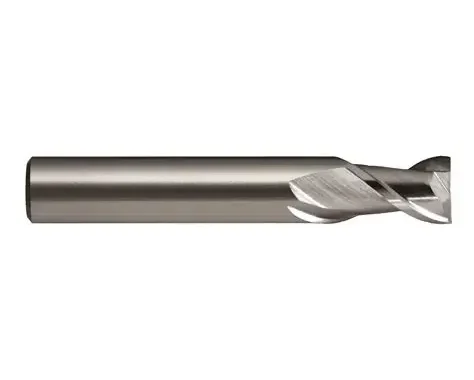

Slot drills are a go-to choice when you’re aiming for cleaner and more accurate cuts in milling work. Whether you’re creating grooves, slots or plunging into material, these tools help keep everything lined up and neat. They’re handy in many types of milling jobs because they cut across both the bottom and side of the…