Exploring End Mills: How to Maximise Their Performance

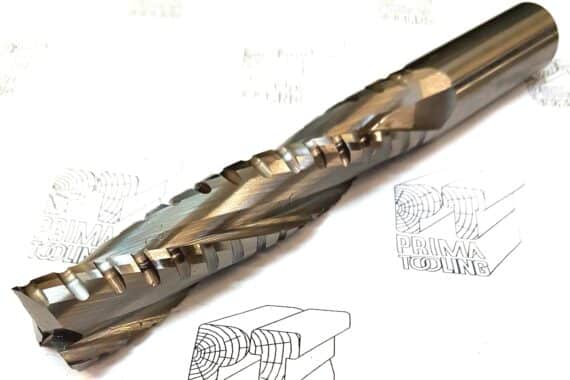

End mills are vital tools in the world of machining, designed to cut and shape materials with precision. Unlike general-purpose drills, end mills are capable of making complex cuts, including slots, pockets, and contours. This versatility makes them a staple in various industries, from woodworking to metalworking. Understanding the different types of end mills and…