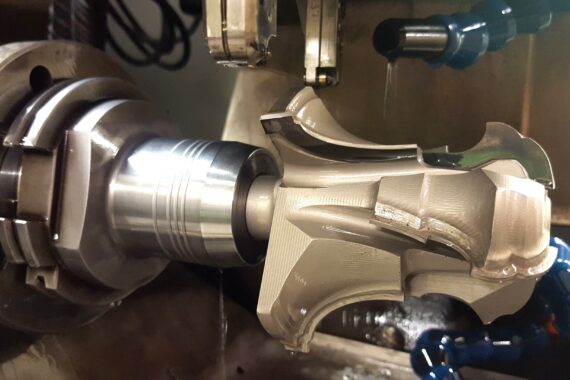

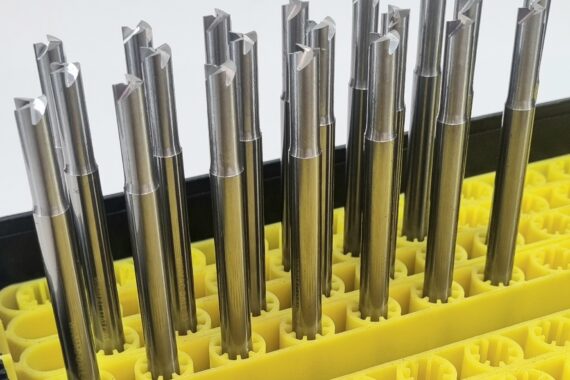

Boost Production with High-Performance Roughing Tools

High-performance roughing tools are essential in modern manufacturing processes. These tools are designed to remove large amounts of material quickly, helping to shape and prepare workpieces for finer finishing operations. They are crucial in industries like automotive, aerospace, and metalworking, where efficiency and precision are key. By understanding and using these tools effectively, you can…